Hydraulic Pressure Testing The Key to Safer and Smarter and More Efficient Systems

When it comes to keeping industrial systems running smoothly, hydraulic pressure testing is your ultimate game-changer. Whether it’s heavy machinery, pipelines, or advanced aviation systems, this process ensures everything operates safely, efficiently, and without costly breakdowns. If your business relies on hydraulic systems, regular pressure testing is not just an option—it’s a necessity.

Let’s dive into why hydraulic pressure testing is essential, how it works, and the game-changing benefits it offers.

What is Hydraulic Pressure Testing and Why Does It Matter?

Think of hydraulic pressure testing as a health check for your machinery. It’s a process designed to test the strength, durability, and safety of hydraulic systems by applying controlled pressure. This ensures your equipment can handle the real-world stresses of operation without fail.

Hydraulic systems operate under enormous pressure—often exceeding 3,000 psi—and a single failure could lead to:

- Expensive downtime.

- Safety risks to employees.

- Environmental disasters like leaks or spills.

By proactively testing your equipment, you can prevent these issues, saving time, money, and headaches.

The Benefits of Hydraulic Pressure Testing

Hydraulic pressure testing isn’t just about meeting regulations; it’s about boosting performance and protecting your business. Here’s why it’s a must-have for any operation:

- Avoid Costly Failures

- Detect and fix issues before they become expensive problems. Think of it as catching a small leak before it floods your operation.

- Increase Equipment Lifespan

- Regular testing identifies wear and tear early, helping you maintain your systems and extend their useful life.

- Enhance Safety Standards

- Keep your workplace safe by reducing the risk of accidents caused by hydraulic failures. It’s a smart way to protect your employees and your reputation.

- Stay Compliant

- Industry standards like ISO and ASME require pressure testing to ensure equipment safety. Compliance isn’t just about avoiding fines—it’s about building trust with clients and partners.

How Does Hydraulic Pressure Testing Work?

The process is simpler than you think but incredibly effective:

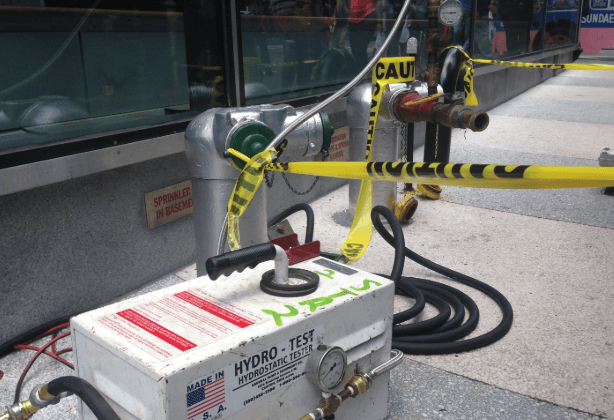

- Preparation: Technicians clean and isolate the system to prepare it for testing.

- Pressure Application: Controlled pressure is applied using hydraulic pumps, simulating real-world conditions.

- Observation: Equipment is monitored for leaks, structural weaknesses, or pressure drops.

- Reporting: Detailed reports identify any issues and recommend solutions to keep your systems running smoothly.

Types of Hydraulic Pressure Testing

Not all hydraulic systems are the same, which is why different testing methods are used:

- Hydrostatic Testing: Uses water or other fluids to test system integrity. Ideal for pipelines and high-pressure equipment.

- Pneumatic Testing: Uses pressurised gases like nitrogen. Perfect for systems where fluids can’t be used, but it requires extra safety precautions.

- Leak Detection Testing: Identifies even the smallest leaks to maintain system efficiency.

- Burst Testing: Pushes a component to its breaking point to understand its limits. This method helps improve future designs.

How Hydraulic Pressure Testing Saves You Money

Investing in hydraulic pressure testing might feel like an extra cost upfront, but it pays for itself many times over:

- Fewer Repairs: Fixing small issues is far cheaper than dealing with catastrophic failures.

- Longer Equipment Life: Routine testing keeps your machines running longer, reducing the need for replacements.

- Boosted Productivity: With fewer breakdowns, your team can focus on getting the job done.

Imagine cutting repair costs by nearly half and avoiding the stress of unexpected equipment failures—this is what hydraulic pressure testing offers.

Choosing the Right Testing Partner

Not all hydraulic pressure testing services are created equal. To get the best results, look for a provider who offers:

- Expert Technicians: Certified professionals with industry experience.

- Advanced Equipment: Modern tools that deliver precise and reliable results.

- Customised Solutions: Testing tailored to your specific systems and operational needs.

- Clear Compliance: A commitment to meeting industry standards like ISO and ASME.

The right partner can make all the difference, ensuring your systems are safe and optimised for peak performance.

Future Trends in Hydraulic Pressure Testing

The future of pressure testing is smarter and more efficient. Technologies like IoT sensors and AI-driven analytics are making it possible to monitor hydraulic systems in real time. Imagine receiving an alert before a failure happens, giving you time to fix the issue without any downtime.

In a world where efficiency and safety are everything, hydraulic pressure testing is your secret weapon. It ensures your systems run smoothly, protects your team, and keeps your operations compliant and productive. Don’t wait for a breakdown to remind you of its importance—invest in hydraulic pressure testing today and experience the peace of mind that comes with knowing your equipment is in top shape.